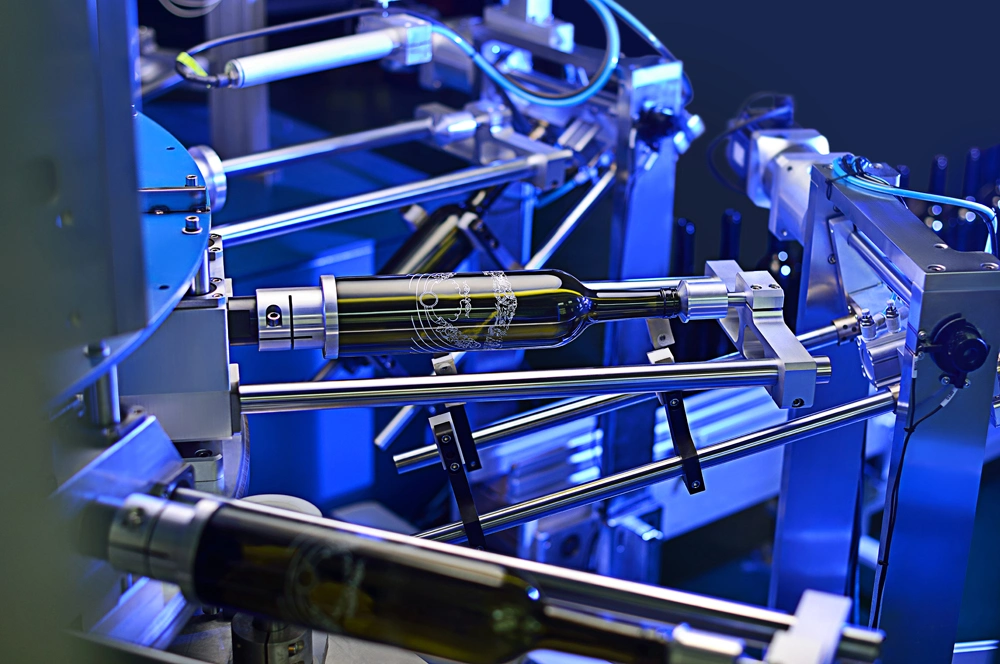

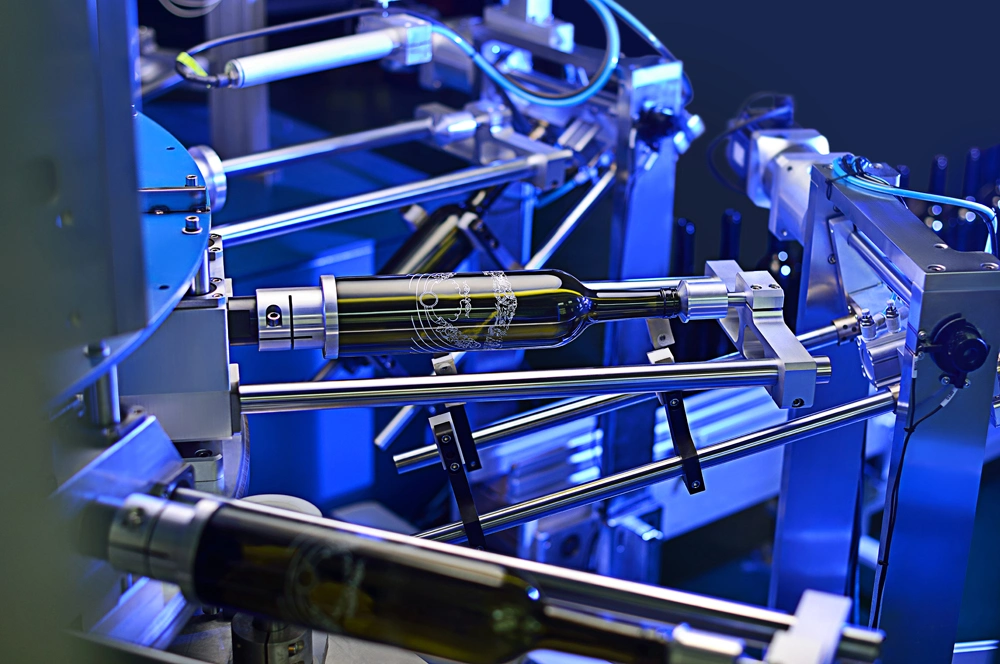

Automatic CNC Controlled 4 Color Glass Wine Bottle Label Trademark Silk Screen Printing Machine

Applications:

Applications:

This multifunctional rotary multicolor screen printing machine is applied to different print pattern and word on cylindrical and oval object.

For example, wine glass bottle, liquor glass bottle, liquor glass bottle, drinking glass bottle, soy sauce glass bottle, glass jars, glass tubes, other glass containers and so on.

Featuring with easy operation, accuracy positioning, highly automation, fast in printing and low maintenance.

Printed samples:

Features:

Parameters:

Machine details:

For example, wine glass bottle, liquor glass bottle, liquor glass bottle, drinking glass bottle, soy sauce glass bottle, glass jars, glass tubes, other glass containers and so on.

Featuring with easy operation, accuracy positioning, highly automation, fast in printing and low maintenance.

Printed samples:

Features:

1. Mechanical register and visual mark register can be achieved. Colour to colour high register accuracy.

2. Controlled by PLC and touch screen display, with kinds of monitor system to ensure the machine running stable and safe at high speed.

3. Equipped with functions, such as:

Vertical or horizontal infeed and outfeed of article,

Orientation,

Antistatic dust device,

Flame pre-treatment,

Automatic pre- and main register,

No article no print,

Conventional UV or LED UV curing system.

4. Mechanical combine with pneumatic driving. Uses photoelectric sensor to control stop point. Simple operation and stable running. High printing precision and quality.

5. All main components are from Taiwan, France, German, USA and Japan to ensure the machine quality and stability of printing.

6. Optional integration of different processing i.e. hot stamping unit and varnishing.

2. Controlled by PLC and touch screen display, with kinds of monitor system to ensure the machine running stable and safe at high speed.

3. Equipped with functions, such as:

Vertical or horizontal infeed and outfeed of article,

Orientation,

Antistatic dust device,

Flame pre-treatment,

Automatic pre- and main register,

No article no print,

Conventional UV or LED UV curing system.

4. Mechanical combine with pneumatic driving. Uses photoelectric sensor to control stop point. Simple operation and stable running. High printing precision and quality.

5. All main components are from Taiwan, France, German, USA and Japan to ensure the machine quality and stability of printing.

6. Optional integration of different processing i.e. hot stamping unit and varnishing.

Parameters:

| Printing speed max | 1800-2100 pieces/hour (depending on article shape, size and print image, infinitely adjustable) |

| Printing area | 280*220mm |

| Compressed air pressure | 6-8 Bar |

| Machine dimension | 5400*5000*2400mm |

| Power | AC 380V, 3-Phase, 50Hz/60Hz, 23Kw(conventional UV), 5Kw(LED UV) |

Machine details: