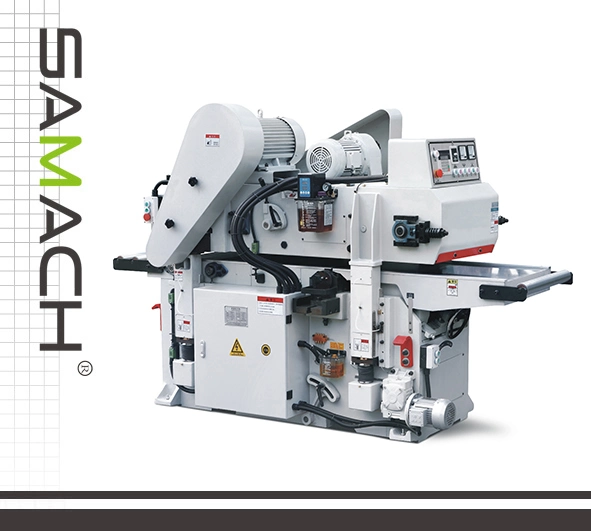

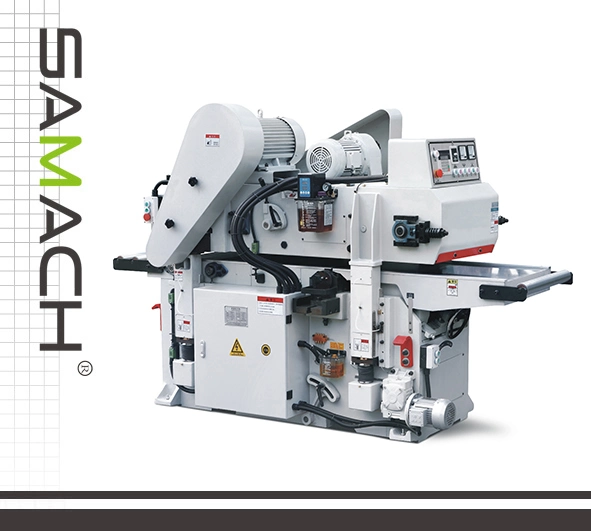

Double-side planer

RMB470A/470B/630A/630B

1.Suitable for double side and fixed-thickness planing tor the boards of thickness under 200mm

2.Adopting frequency control to ensure the efficiency for B series

3.The structure of the bottom cutter shaft can be pulled out quickly which result a more convenient and more secure way to replace or adjust the cutter.

4.The workbench is made of a special weat-resistance material with polishing treatment which could result a high precision and abrasion performance.

5.Schneider electrical elements

6.The precision can up to 0.01mm of the magnetic grating digital readout .input the data to set the working thickness automatically.

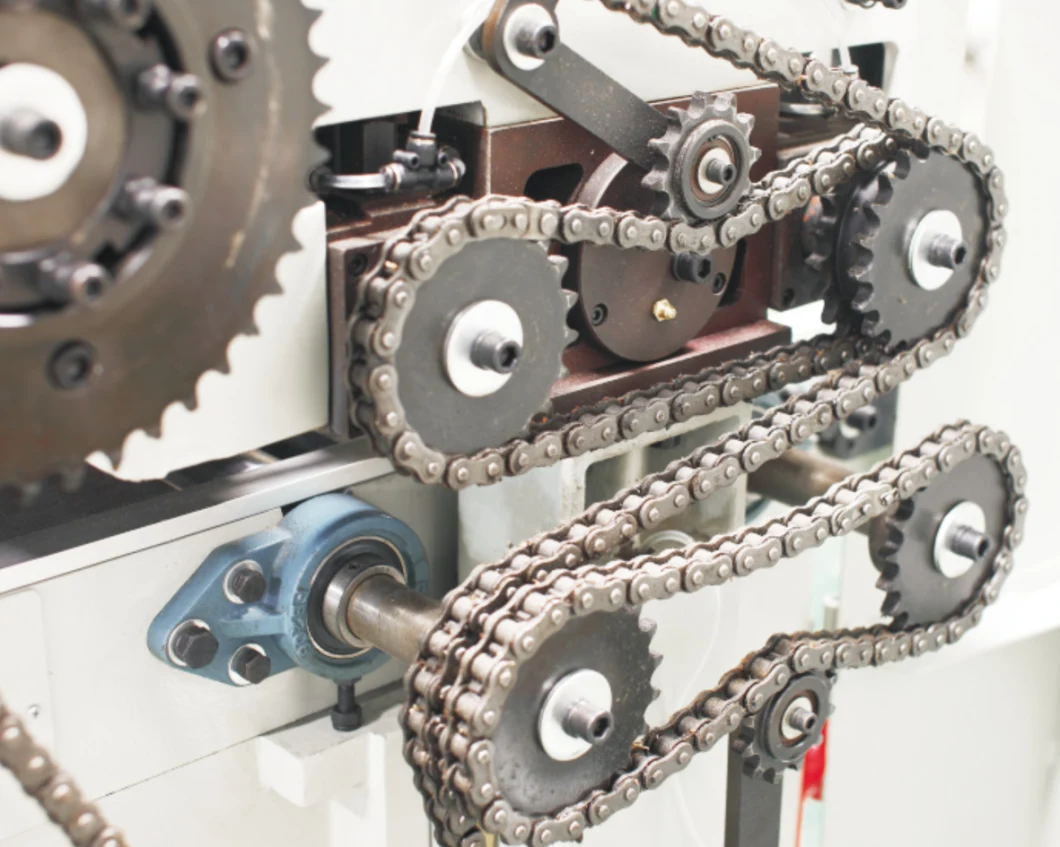

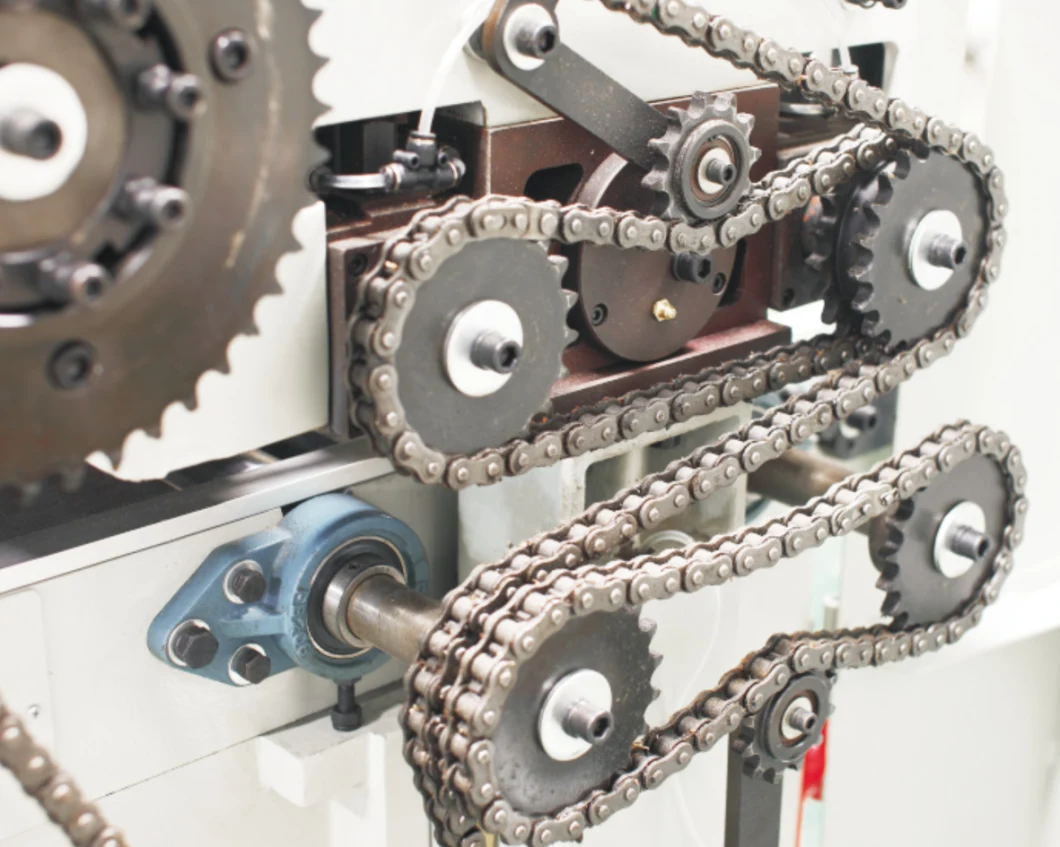

7.The feeding unit can be adjusted up-wards and downwards,the elevating range reaches 6mm, and thus the processing precision can be enhanced with powerful feeding.

8.Provided with driven feed roller structure.ensuring stronger and smoother feeding.equipped with overloading protection mechanism.

9.Equipped with pressure plate guarantees short workpiece smooth machining, increasing production output.

10.Imported automatic lubrication pump for forced lubrication of feeding parts, with oil-free protection function

11.The bearing brand such as TR. NSK. SNR.

12.Short boards,feeding roller shelf device(optional)

13. Automatic thickness measurement and lower limit switch.

12The holders are all resin sand casting to avoid any deformation.

EXHIBITION

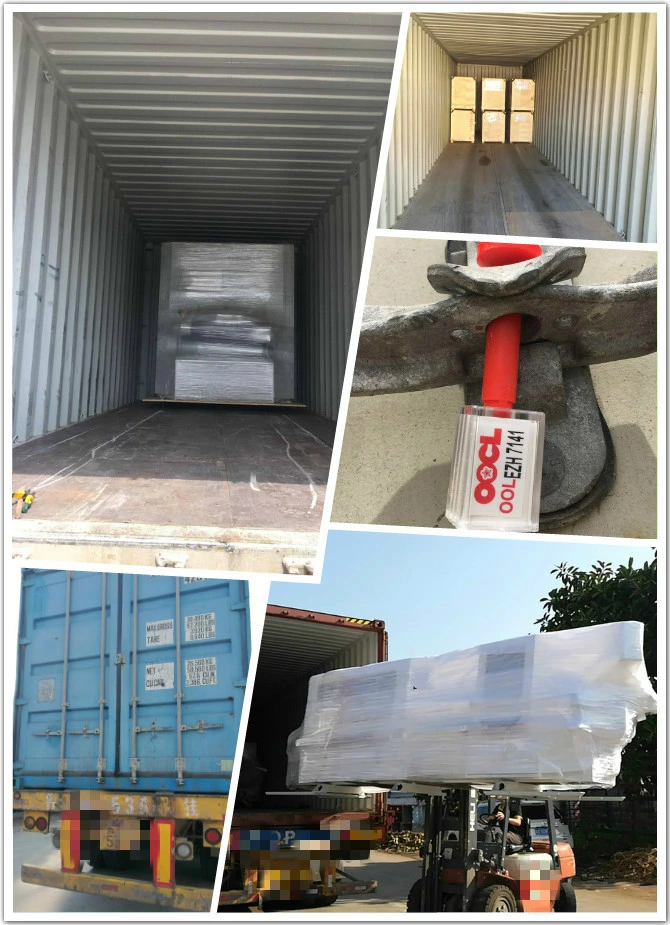

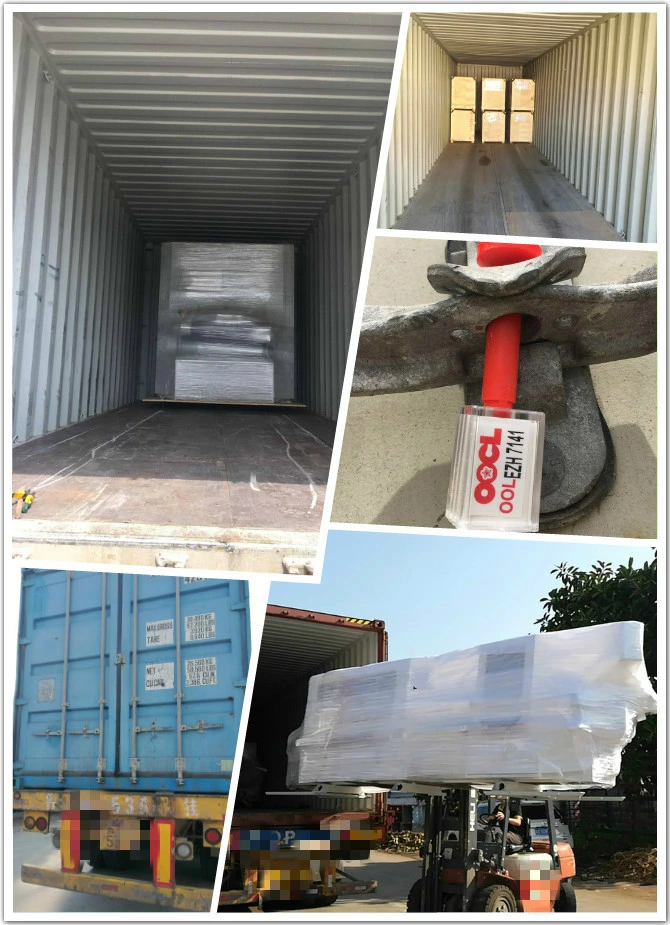

LOADING

RMB470A/470B/630A/630B

1.Suitable for double side and fixed-thickness planing tor the boards of thickness under 200mm

2.Adopting frequency control to ensure the efficiency for B series

3.The structure of the bottom cutter shaft can be pulled out quickly which result a more convenient and more secure way to replace or adjust the cutter.

4.The workbench is made of a special weat-resistance material with polishing treatment which could result a high precision and abrasion performance.

5.Schneider electrical elements

6.The precision can up to 0.01mm of the magnetic grating digital readout .input the data to set the working thickness automatically.

7.The feeding unit can be adjusted up-wards and downwards,the elevating range reaches 6mm, and thus the processing precision can be enhanced with powerful feeding.

8.Provided with driven feed roller structure.ensuring stronger and smoother feeding.equipped with overloading protection mechanism.

9.Equipped with pressure plate guarantees short workpiece smooth machining, increasing production output.

10.Imported automatic lubrication pump for forced lubrication of feeding parts, with oil-free protection function

11.The bearing brand such as TR. NSK. SNR.

12.Short boards,feeding roller shelf device(optional)

13. Automatic thickness measurement and lower limit switch.

12The holders are all resin sand casting to avoid any deformation.

| Models | RMB470B | RMB630B | RMB470A | RMB630A |

| Working thickness | 9-200mm | 9-200mm | 9-200mm | 9-200mm |

| Working width | 10-470mm | 10-630mm | 10-470mm | 10-630mm |

| Min. Working length | 250mm(180mm) | 250mm(180mm) | 250mm(180mm) | 250mm(180mm) |

| Max. Cutting depth | Upper:5mm Bottom:5mm | Upper:5mm Bottom:5mm | Upper:5mm Bottom:5mm | Upper:5mm Bottom:5mm |

| Cutting spindle dia | Ф100mm | Ф100mm | Ф100mm | Ф100mm |

| Cutting spindle speed | 5000r/min | 5000r/min | 5000r/min | 5000r/min |

| Feeding speed | 7-13m/min | 7-13m/min | 3-20m/min | 3-20m/min |

| Upper cutting spindle motor power | 7.5kw | 15kw | 7.5kw | 15kw |

| Bottom cutting spindle motor power | 5.5kw | 7.5kw | 5.5kw | 7.5kw |

| Feeding motor power | 2.2kw | 2.2kw | 2.2kw(VFD) | 2.2kw(VFD) |

| Lifting motor power | 0.37kw | 0.37kw | 0.37kw | 0.37kw |

| Total power | 15.57kw | 25.07kw | 15.57kw | 25.07kw |

| Dust exit dia | Ф150mm | Ф150mm | Ф150mm | Ф150mm |

| Overall size(mm) | 2550×1050×1750 | 2600×1200×1750 | 2550×1050×1750 | 2600×1200×1750 |

EXHIBITION

LOADING