The YZ series ironers are ideal for medium to large size laundries including resort hospitality, health care and commercial laundries. This line of ironers produces high quality linen finishes easily and efficiently. It has high evaporation power and saves energy. The frame is built with high quality carbon steel primed and painted for long life. The cylinder is mirror polished and supported by heavy-duty lubricated bearings. A large efficient fan pulls evaporated moisture away from the cylinder. Nomex ironing straps that prevent absorption of moisture while ironing extrends the life of all feed compartments. The compact design occupies very little space as the finished linen can be discharged to the front or in the back to a folder. These ironers are the most affordable ironers in terms of capital investment, operating expense, maintenance, and floor space requirement. Discover the difference and the elegant and simple features of this ironer line.

A highly sensitive hand protection board ensures ultimate safety in each phase of the ironing process.The seal system uses a high quality swivel joint which ensures a reliable seal and allows easy and simple maintenance.

Our frequency conversion speed adjustment system allows for a continual even flow of speed which brings more energy saving.

Equiped with 2 floatation type condensation traps giving it greater efficiency. This innovative, award winning design has yielded a remarkable degree of energy conservation.

Auxiliary stainless steel brackets allow for max. Stability to each flatwork ironer and eliminates any concerns of rusting.

Features:

(1) Microprocessor control

(2) High productivity with minimum maintenance

(3) Highest water evaporation capacity

(4) Fingerguard protection

(5) Safe and easy to install

(6) User-friendly control. Temperature and/or speed adjustable any time

(7) Frequency inverter

(8) Easy access to all components

(9) Standard automatic cool down

(10) Optimized exhaust system

| Description | YZII-3000/3300 | YZIII-3000/3300 | YZIV-3000/3300 | YZV-3000/3300 | |

| Ironing range(width thickness) | mm | 3000/3300,≤3 | 3000/3300,≤3 | 3000/3300,≤3 | 3000/3300,≤3 |

| Ironing roll diameter | mm | 800*3000/3300 | 800*3000/3300 | 800*3000/3300 | 800*3000/3300 |

| The quantity of roller | unit | 2 | 3 | 4 | 5 |

| Steam pressure | Mpa | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| Ironing speed | m/min | 0-16 | 0-21 | 0-30 | 0-35 |

| Motor power | kw | 1.5 | 2.2 | 3 | 4 |

| Steam pipe diameter | DN | 40 | 40 | 40 | 40 |

| Drain pipe diameter | DN | 20 | 20 | 20 | 20 |

| Steam consumption | kg/h | 260(270) | 380(420) | 480(500) | 580(600) |

| Dimension | mm | 2440*4060*1433 2440*4360*1433 | 3440*4060*1433 3440*4360*1433 | 4440*4060*1433 4440*4360*1433 | 5440*4060*1433 5440*4360*1433 |

| Weight | kg | 3010/3309 | 4388/4824 | 5756/6258 | 7142/8052 |

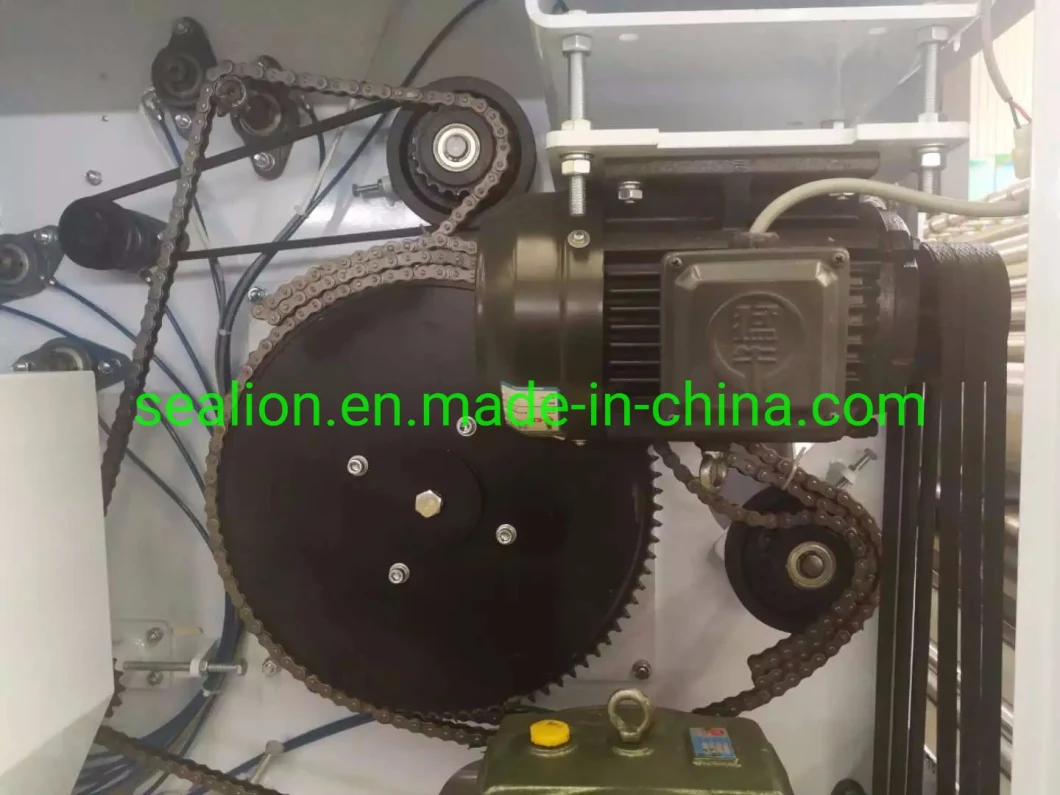

Driven by a combination of belts and chains , the drive system is robust , and delivers accurate consistent speeds.

Spindle tape drive is used instead of canvas for smooth transfers .

The steam inlet is sealed with rotary joints to avoid leakage and ensure a long servicce life .