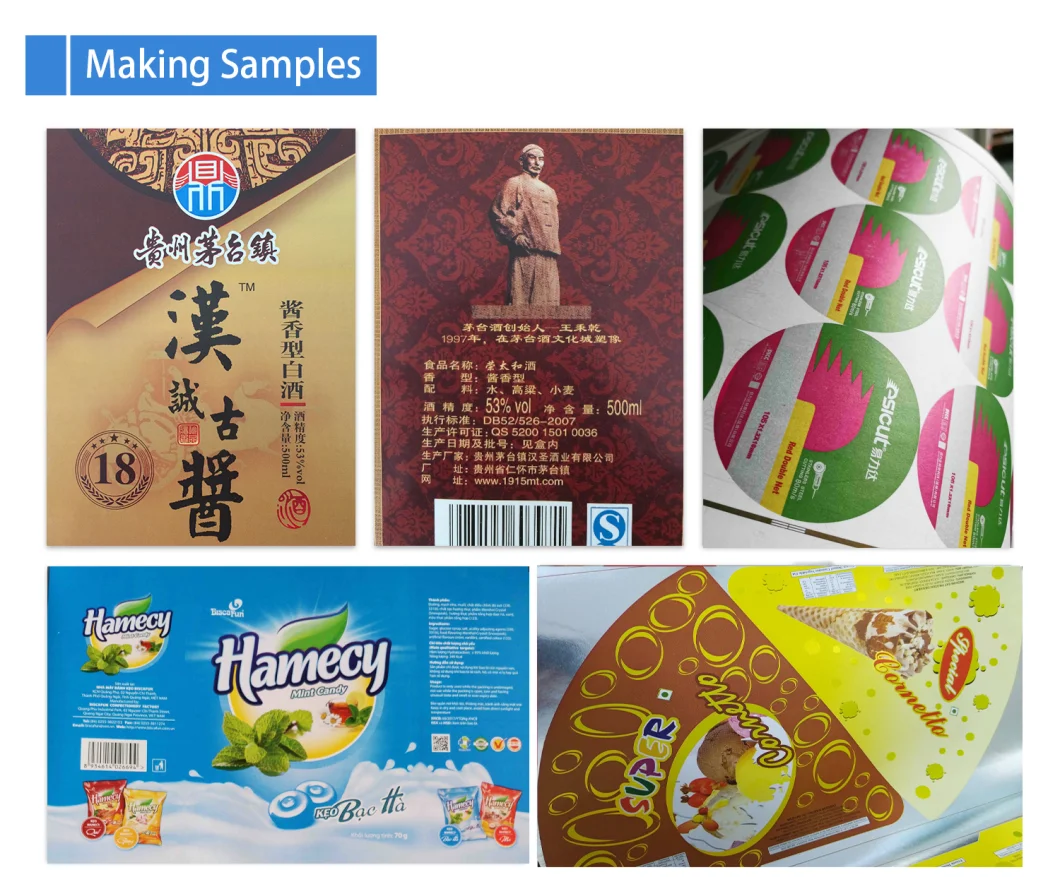

Application:

Our Flexo Printing Machine is widly used for printing narrow material, and it 's an ideal machine for printing narrow size label etc.

Suitable Material:

Self Adhesive paper , Self -Adhesive Film , Laminating Film ,Paper ,Opp ,Alumium,CPP ,PET .

Characteristics:

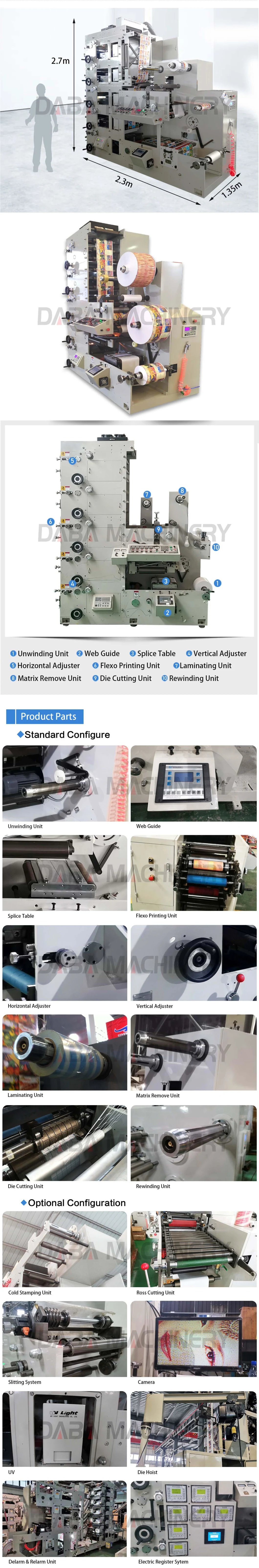

1, Ceramic anilox cylinder are adopted for ink transferring.

2, The unwinding and rewinding units are designed with magnetic powder brakes and clutchs for tension control, and flexo

machine equipped with Mitsubishi auto tension controller.

3, Each printing unit is adopted 360°printing plate-adjustment.

4, All printing units are equipped with a group of hot air dryer.(UV dryer is for option)

5, The machine has one die-cutting station, and it can make printing and die cutting finished in one process.

6, The ink rollers will be automatically separated from the printing roller, and it will keep rotating at a low speed, thus

preventing ink from drying.

7, The main motor is equipped with an imported variable frequency stepless speed govermor. This guarantees the stable

performance of flexo press.

8, The machine can finish material-feeding, printing, vanishing, drying, laminating, die-cutting and rewinding at one stroke.

It is an ideal machine for printing trade invoice and top-grade adhesive label.

Standard Configuration for flexo printing machine:

1.One Paste plate machine

2.One anilox roller for each group (LPI is optional, made in shanghai)

3.Three sets printing rollers (3*5=15) Printing Teeth User Advise .

4.Printing both sides at the same time (with Turn bar)

5.With the lamination station

6.Die cutting station.

7.One unwinding tension controller

8.One rewinding tension controller

9.magnetic power brake